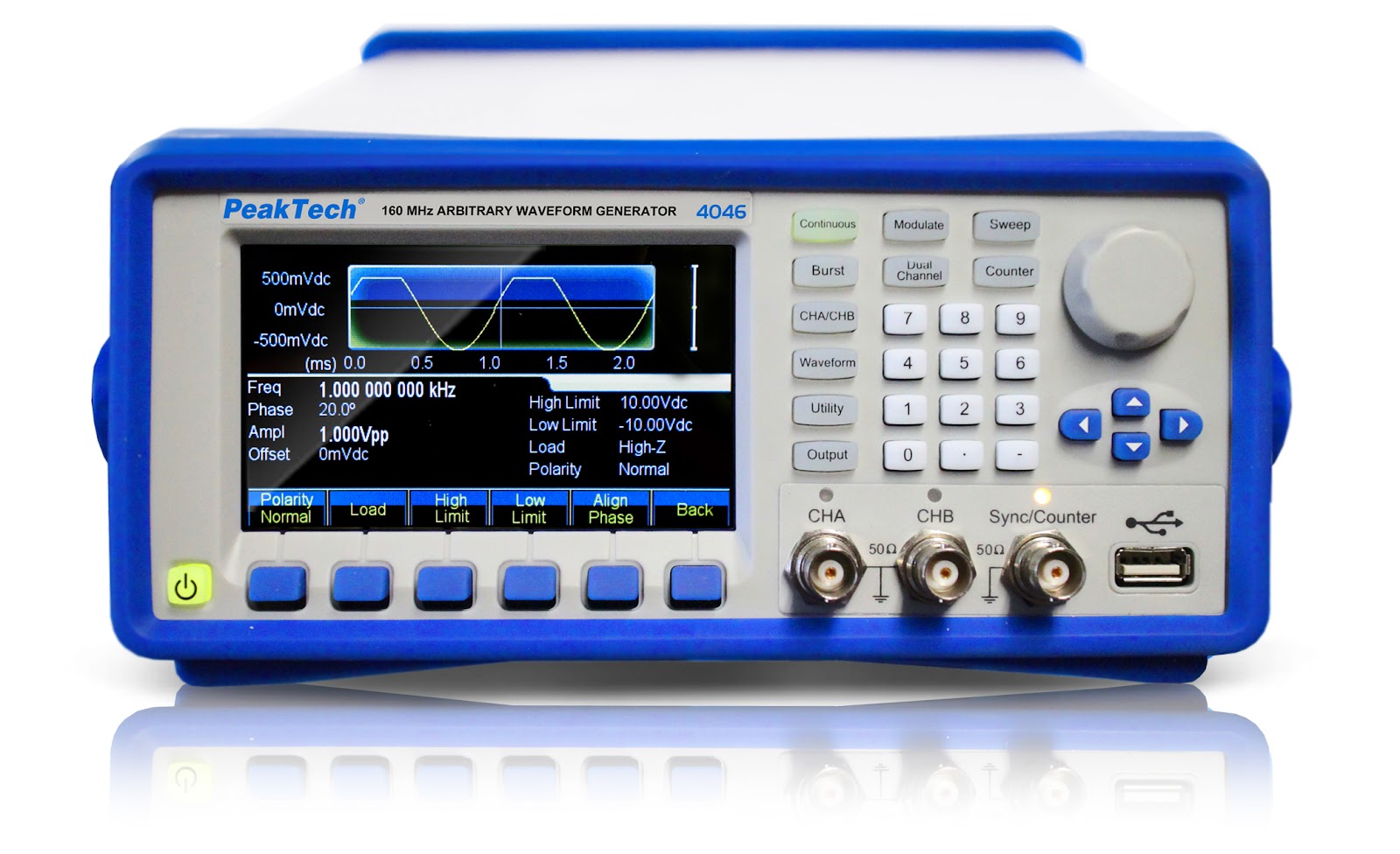

Great question! A signal generator (also known as a function generator) is another very useful tool for electronics repair and testing. While a digital oscilloscope helps you see signals, a signal generator helps you inject known signals into the circuit. This makes fault-finding and performance testing much easier—especially in analog audio, RF, communication, and digital circuits.

🛠️ How a Signal Generator Helps in PCB Repair

🔹 1. Testing Amplifiers and Audio Circuits

When repairing audio amplifiers or speaker systems:

-

You can inject a 1kHz sine wave into the amplifier input.

-

Observe the output on the oscilloscope.

-

A clean sine output means the amp is working fine; distortion, clipping, or no signal means there’s a problem.

✅ Real Use: I once repaired a PA amplifier by injecting a test tone. The preamp stage was fine, but the power stage wasn’t amplifying. Tracing the signal stage by stage helped isolate the faulty transistor.

🔹 2. Troubleshooting Stages in Signal Path

In communication or processing circuits, you can:

-

Inject square waves or pulse trains.

-

Check how each section processes the signal.

This is useful in:

-

Filter circuits – To test frequency response.

-

Digital logic ICs – To simulate clock or data inputs.

-

Timing circuits (e.g., 555, counters) – To trigger or reset circuits.

🔹 3. Testing Oscilloscope and Probes

You can also use the signal generator:

-

To calibrate or verify that your oscilloscope probe is working correctly.

-

To test bandwidth and distortion measurement setups.

🔹 4. Simulating Missing Signals

In faulty boards, sometimes the microcontroller, clock circuit, or sensor isn't producing signals. A signal generator can simulate those inputs to test whether the next stage works.

✅ Real Use: In one project, a dead IR receiver circuit wasn’t triggering the output stage. I injected a 38kHz modulated signal using the generator and confirmed that the output section worked. So the IR sensor was faulty.

🔹 5. Component Testing

Some passive components (filters, transformers) and even certain ICs can be tested by applying known signals:

-

Use sweep function to test filters.

-

Inject low-frequency signals to check transformer or coupling capacitor behavior.

📊 Summary Table: Where Signal Generator Helps

| Application | Signal Used | Purpose |

|---|---|---|

| Audio amplifier testing | Sine wave (1kHz) | Check output stages |

| Digital logic | Square wave | Simulate clocks/data |

| IR/remote circuit | 38kHz modulated | Test receiver function |

| Filters/RC circuits | Frequency sweep | Analyze response |

| Faulty microcontroller | Pulse | Simulate missing trigger |

| Signal tracing | Any waveform | Track signal path with scope |

🔧 Final Words

A signal generator + oscilloscope is a powerful combo. You inject a test signal using the generator and observe the circuit's response using the scope. Together, they help:

-

Reduce guesswork

-

Find open signal paths

-

Verify functionality stage-by-stage

-

Speed up complex repairs

Whether you are working on LED TVs, amplifiers, SMPS, or embedded boards, the signal generator is a must-have tool for serious electronics repair.

Absolutely! A signal generator is very helpful in troubleshooting SMPS (Switched-Mode Power Supply), especially during fault-finding and when the control IC is not producing signals, or when you're checking gate drive, transformer behavior, or startup problems.

Here’s a clear breakdown of how a signal generator helps in SMPS repair:

⚡ How Signal Generator Helps in SMPS Troubleshooting

🔹 1. Simulate PWM Gate Signals

Many SMPS circuits use a PWM IC (like UC3842, TL494, SG3525, etc.) to drive MOSFET gates. If the IC is dead or not producing output, you can:

-

Inject a PWM signal (e.g., 20kHz–100kHz, 5V peak) from the signal generator into the gate of the MOSFET (through a gate resistor).

-

Observe whether the transformer starts switching and output voltage appears.

✅ Real Example: I had a dead SMPS where the PWM IC was faulty. Injecting a 50kHz square wave to the gate proved the power stage was fine. Only the control circuit needed repair.

🔹 2. Testing Transformer Behavior

Injecting a square wave into one winding of a transformer allows you to:

-

Check for proper inductive behavior (waveform on secondary).

-

Identify shorted turns or open windings.

-

Observe waveform ringing or distortion if the transformer is damaged.

Use low voltage (1–5V) and limited current to avoid damage.

🔹 3. Triggering Protection Circuit Debugging

Some SMPS have over-voltage, over-current, or feedback protection. If the SMPS shuts down instantly, you can:

-

Inject a test signal into the feedback or sense line.

-

Confirm whether the protection is falsely triggering.

✅ Example: One supply had a feedback pin stuck high. Injecting a 2V DC + ripple waveform showed that the supply would restart only when FB was normal. Fault traced to an open opto-coupler.

🔹 4. Clock Injection in Synchronous Designs

Some SMPS designs (especially digital ones) use external clock sources. If the clock crystal or oscillator fails:

-

You can inject a square wave clock signal into the IC’s clock input.

-

If SMPS starts working, it confirms clock section is faulty.

🔹 5. Output Ripple Simulation for Post-Regulator Testing

If the output of SMPS feeds another regulator (e.g., LDO), you can:

-

Inject a signal with ripples or noise to the input.

-

Observe how the next stage handles it (ripple rejection, filtering, etc.)

🧪 Caution When Using Signal Generator on SMPS

| Do's | Don'ts |

|---|---|

| Use low-voltage signals (5V max) when injecting into gates or transformer | Don’t inject high voltage directly—can damage components |

| Always isolate ground between signal generator and live SMPS | Never connect signal generator ground to high-voltage circuits directly |

| Use series resistors (1k–10k) to limit current | Avoid driving directly without limiting circuit |

✅ Summary Table

| Purpose | Signal Type | Use |

|---|---|---|

| Test gate drive | 20–100kHz square wave | See if MOSFET and transformer respond |

| Test transformer | 1kHz–10kHz square wave | Check for waveform on secondary |

| Debug feedback | Ramp, DC + ripple | Simulate normal feedback signal |

| Replace missing clock | Square wave (fixed freq) | Restart controller temporarily |

| Verify filtering | Noisy sine or burst | Test post-regulator behavior |

🛠 Real World Tip

When debugging a dead SMPS, combine:

-

Signal Generator to inject known signal into gate or feedback,

-

Oscilloscope to monitor output and switching behavior.

This speeds up repair and avoids blind trial-and-error.

Regards

No comments:

Post a Comment